“

Built for a Sustainable Future

From the very beginning, Witchburn was conceived as a Net Zero distillery. Unlike traditional distilleries that rely on oil or gas, Witchburn operates without fossil fuels. Every step of production is powered by renewable energy.

Sustainability here is more than technology – it is a philosophy. By re-using existing buildings instead of constructing new ones, by carefully planning every detail for long-term efficiency, and by treating by-products as valuable resources, Witchburn is committed to a lighter footprint and a responsible future.

Key Elements of Sustainability

- Electroboiler – large-scale electric boiler, powered entirely by renewable wind energy

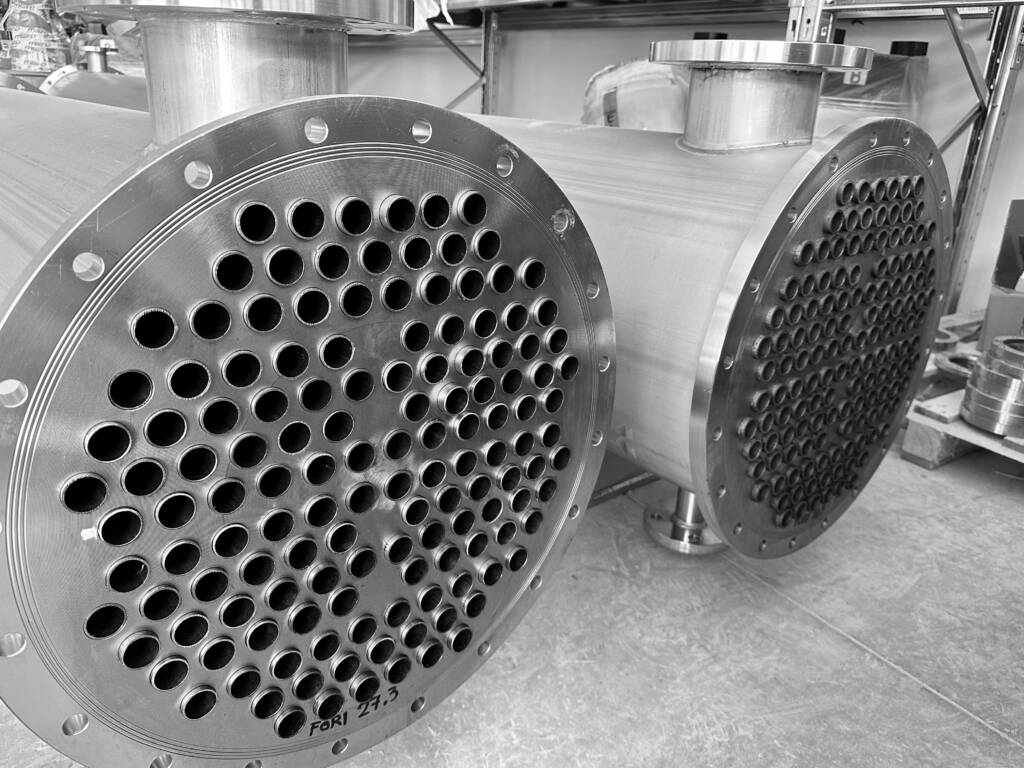

- Mechanical Vapour Recompression (MVRs) – reusing vapour energy for maximum efficiency

- Extremely slow distillation for maximum copper contact

- Heat Recovery – capturing and reusing energy throughout the process

- CO₂ Capture – large parts of the CO₂ generated during fermentation are actively captured

- By-Products – draff and pot ale are treated and reused in sustainable ways

- Re-Use of Existing Structures – the conversion of a former US Navy SEALs building saved vast amounts of materials and avoided emissions from new construction

Reuse of draff in local farms

Pot ale will be used as a natural fertiliser.

Operation with steam generated solely from electricity

More than 90% heat recovery

100% electricity from wind and solar